- Improved Compliance

- Real Consumer Engagement

- Enable Digital Reorder

& Replenish

All About Bioplastics: Are They Really Better?

What is Bioplastic?

According to the American Society for Testing and Materials , a bio-based material is an organic material where carbon is taken from a renewable resource via a biological process.

In simpler terms, bioplastics are made from plants. For instance, these plastics are made from cellulose, which is derived from trees and plants – the main substance used to create these plastics comes from “biomass” (meaning renewable bio-organisms that are living or have recently been alive.)

Most bioplastics on the market today are made from starches or cellulose, both renewable resources. Sugar cane and corn are the most common plants used to generate starch or cellulose.

Is Bioplastic Different than Biodegradable Plastic?

Yes, these two forms of plastic very different. Although commonly assumed that all bioplastic is biodegradable, it is not. Biodegradable materials mean that when environmental conditions are correct, the environment can break down biodegradable plastic in a relatively short period of time (weeks to months).

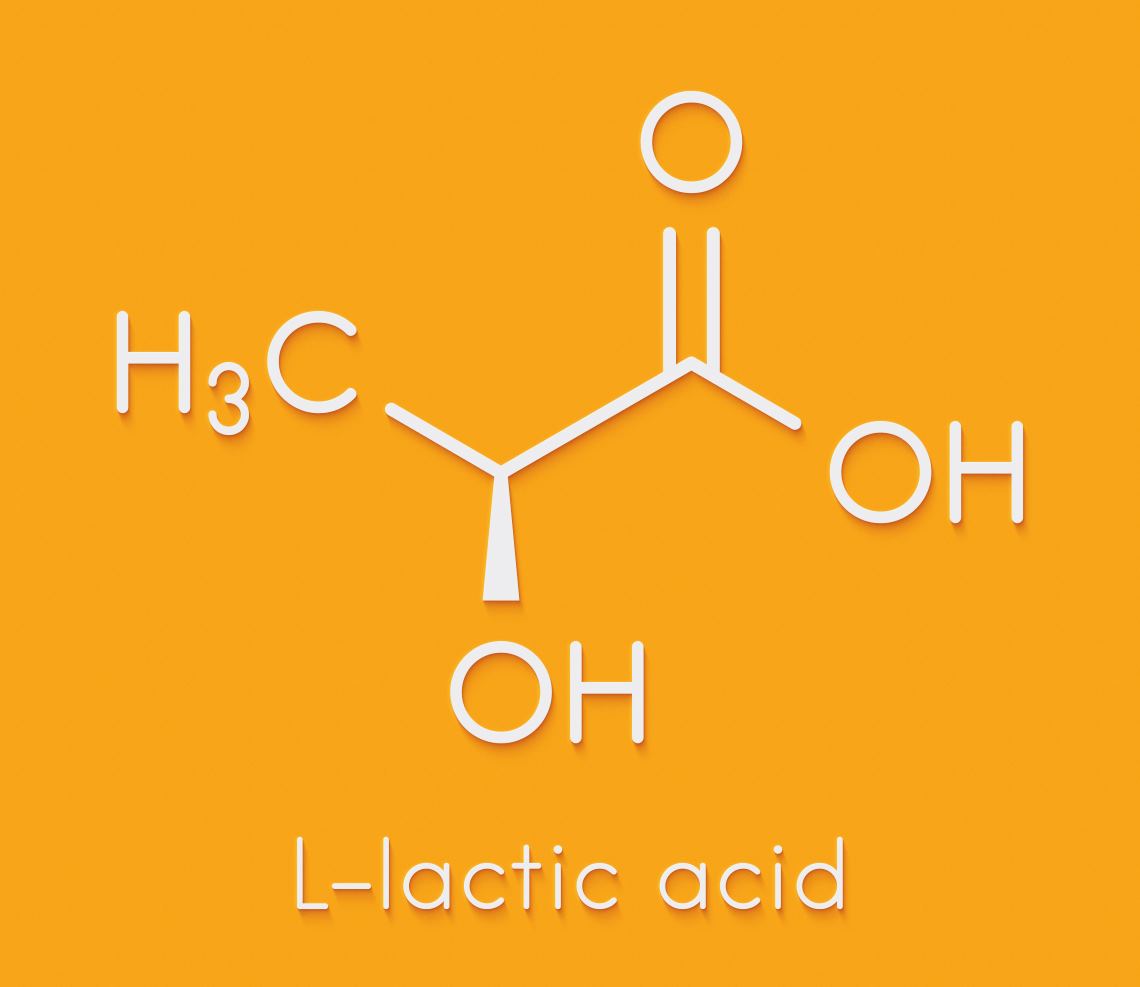

Just because a term incorporates “bio” does not automatically mean it is biodegradable as a finished product. Take polylactic acid (PLA) as an example. PLA is made from plant material and is biodegradable when in a commercial composting facility. On the other hand, PET plastic is also made from plant material, but it is not considered biodegradable and will not break down in the environment or a specialized facility.

How is Bioplastic Different Than Conventional Plastic?

We have already looked at bioplastic, what it is, and what it’s made from. So, how is it different than conventional plastic? Let’s take a closer look.

Conventional plastic is derived from petroleum or petrochemicals. These chemicals are completely or mostly synthetic. Conventional plastic is not made from renewable resources, like bioplastics. Generally, most of the conventional plastic is non-biodegradable and has a multitude of devastating effects on ocean life and other environments.

Benefits of Bioplastic

There is a wide range of benefits to using bioplastics over conventional forms of petroleum-based plastics. Overall, bioplastic has a much smaller environmental footprint compared to conventional plastic. Additionally, bioplastics tend to equal a less polluted ecosystem on our planet, but only if they are discarded properly.

Bioplastics are made from a large variety of renewable resources such as corn, sugarcane, or even orange peels, so non-renewable resources – like petroleum – is not heavily relied upon.

BPA in conventional plastic has also become an increasing concern to the general public. Within the last few years, many of the plastic water bottles, baby bottles, food packaged, and other plastic-based containers are now touting that they are BPA-free. Some studies have suggested that BPA can disrupt hormonal activity.

Furthermore, depending on what the bioplastic is made from, the manufacturing process may result in a reduction of greenhouse gasses.

Disadvantages of Bioplastic

Bioplastics are challenging for everyday people, like us, to distinguish from conventional or non-biodegradable plastics. Bioplastics look and feel exactly the same as traditional plastic, so it is challenging, and often inconvenient, for people to tell which type of plastic they have.

For that reason, the customer will just throw the plastic cup or package into a recycling bin and it will all go in a landfill anyway. Additionally, many recycling facilities do not have the means of checking different types of plastics (whether it is conventional or not) – leading to all plastics, including bioplastic and biodegradable plastic, landing in a landfill.

Say a bioplastic and biodegradable cup finds its way into a landfill site. That cup will have a much harder time degrading than if it was exposed of properly. Essentially, this issue would defeat the purpose of biodegradable plastic.

Final Thoughts

Many people believe bioplastic has the potential to replace conventional petroleum-based plastics in the future, but only if some much needed changes are made.

Bioplastic’s benefits have great advantages over conventional plastic – it’s made from renewable resources, may be biodegradable, reduces greenhouse gasses during manufacturing, and more.

However, there are still many kinks to work out with bioplastic practices, like disposing of the items properly and making sure they do not wind up in landfills. Once these issues are effectively addressed, bioplastics could one day fully replace the use of conventional plastic.